ACity Students Engineer an Automated Packaging System

A multidisciplinary team of final-year students from mechanical, electrical, and computer engineering came together to design and build an automated packaging system as part of the Industrial Robotics and Automation (ME/CE/EE 4177) course.

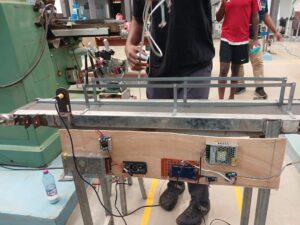

The team developed a flat-belt conveyor synchronized with a four-degree-of-freedom articulated robotic arm, creating a working pick-and-place line. The system combined mechanical fabrication, electronics, IR sensing, and Arduino-based control using servo and stepper motors. Every component was designed to work together under real constraints, mirroring the challenges found in industrial automation environments.

Beyond meeting academic requirements, the project showed how locally fabricated, low-cost automation can improve efficiency, safety, and productivity in small-scale manufacturing and packaging settings. For the students, it was a demanding but rewarding experience that sharpened their technical skills and tested their ability to collaborate across disciplines.

Team Members:

Doreen Edwina Owoo, Paa Kwasi Kesse Manfo Owusu, Fiifi Adom Acheampong, Roderick Tantuoyir, Setornam Koku Dedey, Christina Suzane Agbezukin, Delasi Richards, Makafui Quist, Nana Yaw Asamoah, Bempa Dwomoh, Mohamed Rene Joly, Kofi Nkunim Owusu-Yeboah

- Leadership Lessons from the She Builds Conference: Maureen Amago’s Experience

- Linda Akosua Essilfie: Amplifying Youth Voices on Climate Action at SDG Hangouts

- From Africa to the World: Inside Dabone Abdoul Latif’s Journey of Innovation and Youth Leadership

- ACity Students Engineer an Automated Packaging System

- ACity Students shine at the 7th Edition of Packaging Research and Innovation Challenge